This is a scheme to divert storm water away from Portsmouth's victorian combined system, which comprised of several sites that collectively alleviate the flooding.

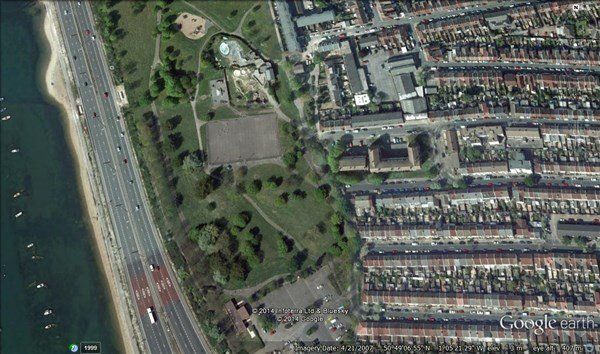

I spent nearly a year as site engineer on Gruniesen Road pump station which basically is a new 12m deep 13.5m shaft in Stamshaw Park which houses 4 pumps that have enough oomff to push storm water out the outfall even at high tide. This involved building a 4mØ chamber on the existing 1200Ø storm water pipe, then another chamber of the same size to change the direction, then into the new 13.5mØ pump station, then another 4mØ chamber to connect back onto the main storm line. This was a great job - 4 reasonably deep chambers with connecting pipework, the main chamber had RC walls, pump stools, pipes in, pipes out, core drilling. The key thing here was positioning the pump stools perfectly. Southern water wanted the cover slabs positioned first and then the pumps dropped in on the guide rails to the pump stools - there were a few anxious faces but i knew it would all fit!! The cover slab consisted of 18 precast units weighing up to 18t which I had to position to form the pump openings.

- 1x 13.5mØ x 12m deep pump station with lorry access

- Various cast insitu slabs, walls, pump stools, benching etc

- 1200Ø concrete pipes in, 1200Ø steel pipes out

- 1x4mØ x 4m deep chamber ontop of the existing storm sewer

- 1x4mØ x 4m deep bifurcation chamber

- 1x4mØ x 4m deep chamber back on to the existing storm sewer

- 300m of ducting through the park to the existing pump station control room and landscaping back to a park

- 650m long channel, some swale some 7.5m wide channel through Portsmouth Golf Course

- Forming landscape features out of the arisings

I also spent 8 weeks or so putting a channel through portsmouth golf course. This is where I learnt how to use LSS. The original plan was to dig the channel, which was 685m long and approx 7m wide, using a GPS controlled excavator. I drew up the channel design in a 3d format and could then not only quantify the muck arisings, but also work out where we could place them to be incorprated as "features" on the golf course. With a bit of help from ScanLaser we got the model, GPS base station and the digger communicating. However the driver didnt feel confident with it so it was back to batter rails and profiles.